Table of Contents

Introduction

When a commercial air conditioning compressor fails during Culver City’s peak heat, the impact can be immediate, costly, and severely disruptive. For property managers and business owners, a non-functioning AC unit not only jeopardizes occupant comfort but can also threaten equipment, inventory, and productivity. In these high-stress moments, emergency air conditioning compressor repair services become an indispensable lifeline–delivering rapid response, technical expertise, and the peace of mind needed to navigate urgent HVAC crises.

This article serves as a comprehensive guide to emergency compressor repairs, focusing on frequently asked questions such as: What situations warrant immediate repair?, How quickly can services be rendered?, Are emergency repairs more expensive?, Which models are most at risk?, and Do urgent fixes come with reliable warranties? Each aspect is addressed with evidence-based insights, tailored to empower Culver City’s commercial stakeholders with the knowledge to protect their facilities and budgets.

Importance of Emergency AC Compressor Repair

Emergency compressor repairs are defined by their critical, time-sensitive nature. In Culver City’s climate, where summer temperatures regularly exceed 90°F, prompt intervention is vital for maintaining safe interior environments in commercial spaces. Loss of cooling can quickly spiral into significant business downtime, discomfort for staff or patrons, and even equipment damage.

Fast, professional interventions–such as emergency air conditioning compressor repair and emergency AC compressor repair Culver City–restore operations swiftly, minimizing both risk and revenue loss. These urgent services make the difference between a short-lived inconvenience and a full-blown operational crisis.

Scope and Purpose of This Article

The primary goal of this article is to inform and support the commercial property management and business community in Culver City. Whether facing an unexpected system outage or seeking to avoid future emergencies, readers will learn about:

– The diagnostic and repair process

– Typical repair timeframes

– Factors driving emergency costs and warranty options

– The role preventive commercial HVAC maintenance plays in reducing risk

– Innovations in energy-efficient AC repair benefiting commercial buildings

Armed with these details, Culver City stakeholders can confidently select providers and strategies that maximize uptime and longevity for critical HVAC assets.

Understanding Emergency AC Compressor Repair

Infographic detailing the diagnostic and repair process for emergency air conditioning compressor failures emphasizing rapid and same-day services in Culver City.

Defining Emergency Repairs

An emergency AC compressor repair arises when a compressor–the central component responsible for circulating refrigerant–fails suddenly, causing a total or severe loss of cooling. These emergencies are most common during peak operational loads (hot afternoons, weekends, or after-hours), when equipment is under maximum strain.

Situations that demand emergency attention include:

– Sudden and total cooling loss during high-temperature periods

– Compressor not starting or repeatedly tripping circuit breakers

– Electrical burning smells or loud metallic noises from the outdoor unit

– Major refrigerant leaks rendering cooling impossible

Given the urgency, 24/7 emergency repairs are prioritized to minimize operational disruption and restore safe working conditions.

Common Causes of Compressor Failure

The most frequent compressor failure causes in commercial AC systems include:

– Electrical Issues

: Power surges, faulty relays, damaged capacitors, or wiring failures.

– Refrigerant Leaks

: Low refrigerant levels cause overheating and excessive wear on the compressor.

– Mechanical Wear

: Age, inadequate lubrication, or factory defects can lead to internal component failures.

– Poor Maintenance

: Clogged coils, dirty filters, and neglected systems increase compressor stress and risk.

Older models–especially those with rotary compressors–may see accelerated failure rates in high-use settings. Regular inspections and prompt attention to unusual noises or performance drops are vital warning signals.

Diagnostic and Repair Process

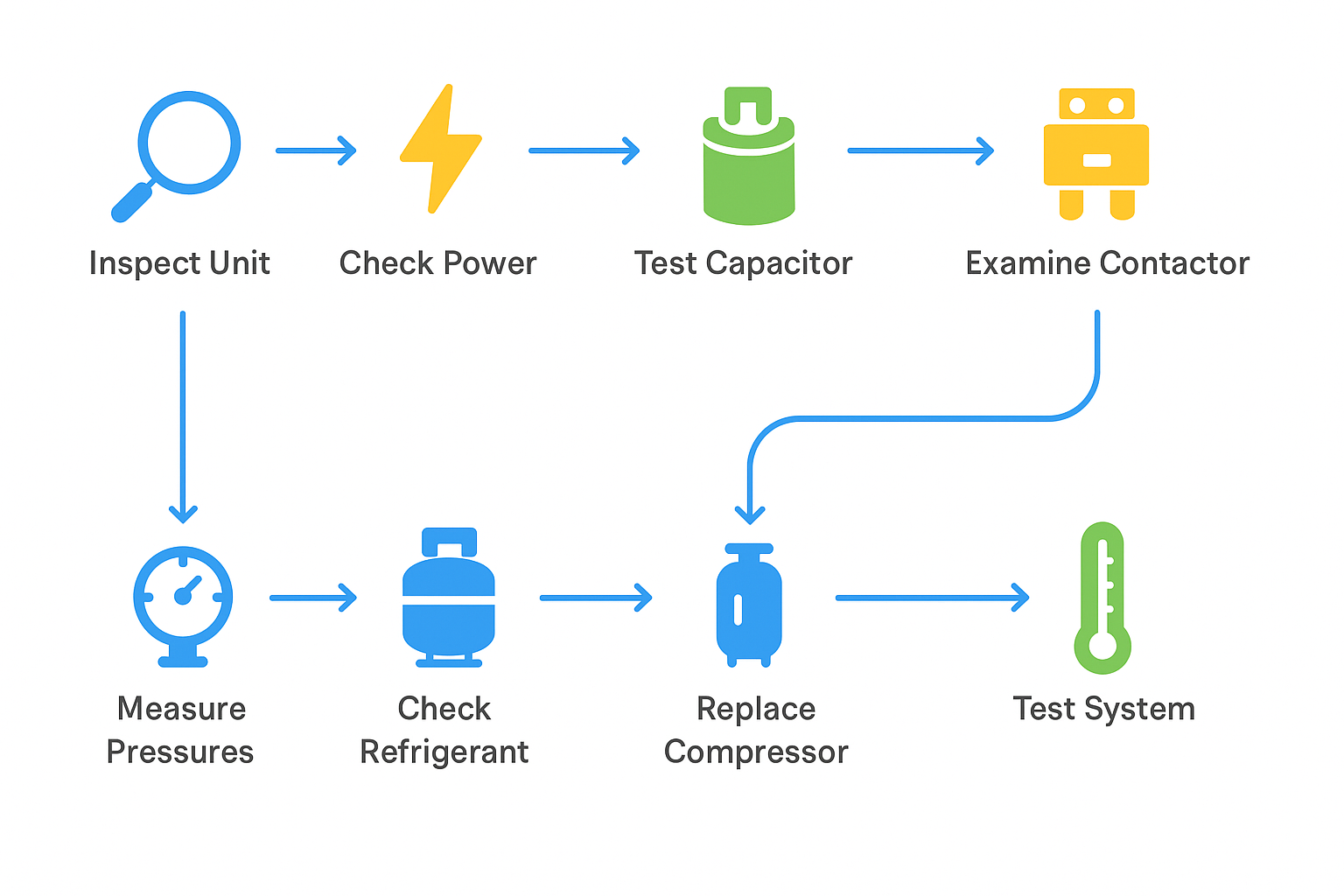

When an emergency call is placed, experienced technicians follow a systematic diagnostic and repair process to identify the root cause and determine the best solution:

1. Inspection of the unit and electrical components using professional instruments.

2. Testing refrigerant pressure, compressor current draw, wiring, and overload protection.

3. Diagnosing whether repair or complete AC compressor replacement is required.

4. Executing repairs–replacing faulty components, recharging refrigerant, or installing a new compressor as needed.

Throughout, clear communication and cost transparency are maintained–hallmarks of professional and commercial AC repair services in Culver City.

Speed and Cost of Emergency Repairs in Culver City

Typical Repair Timeframes

During peak heat, speed is paramount. Most fast AC compressor repair services in Culver City respond within hours of an emergency call, aiming for same-day resolution whenever possible. The average repair timeframe typically ranges from a few hours (for common failures with available parts) to a full business day for more complex needs.

Key timeline factors include:

– Parts Availability: Standard components can minimize downtime. Unique units or custom parts may add delay.

– Technician Experience: Professionals well-versed in local models expedite diagnostics and repairs.

– Operational Constraints: Night, weekend, or holiday breakdowns may impact crew availability.

Rapid response can prevent further damage, loss of business, and excessive discomfort–a critical advantage of emergency HVAC repair services.

Cost Comparison: Emergency vs. Regular Repairs

While urgent response is invaluable, emergency repairs typically cost more than scheduled maintenance. Premium pricing reflects:

– After-hours labor and overtime charges

– Expedited parts delivery

– Priority scheduling for critical commercial accounts

On average, emergency compressor repair costs can be 1.5 to 3 times higher than standard, non-urgent repairs. However, swift fixes can ultimately save money by avoiding prolonged downtime, inventory loss, or further equipment damage.

Factors Influencing Repair Costs

Multiple variables combine to determine final emergency repair pricing:

– Type and Age of AC System

– Severity of Compressor Failure

– Part Brand/Availability

– Expertise of the Technician

– Location and Hour of Service

Proactive commercial HVAC maintenance reduces the risk of costly emergencies by catching early warning signs and ensuring optimal operation.

AC Models Prone to Compressor Failure

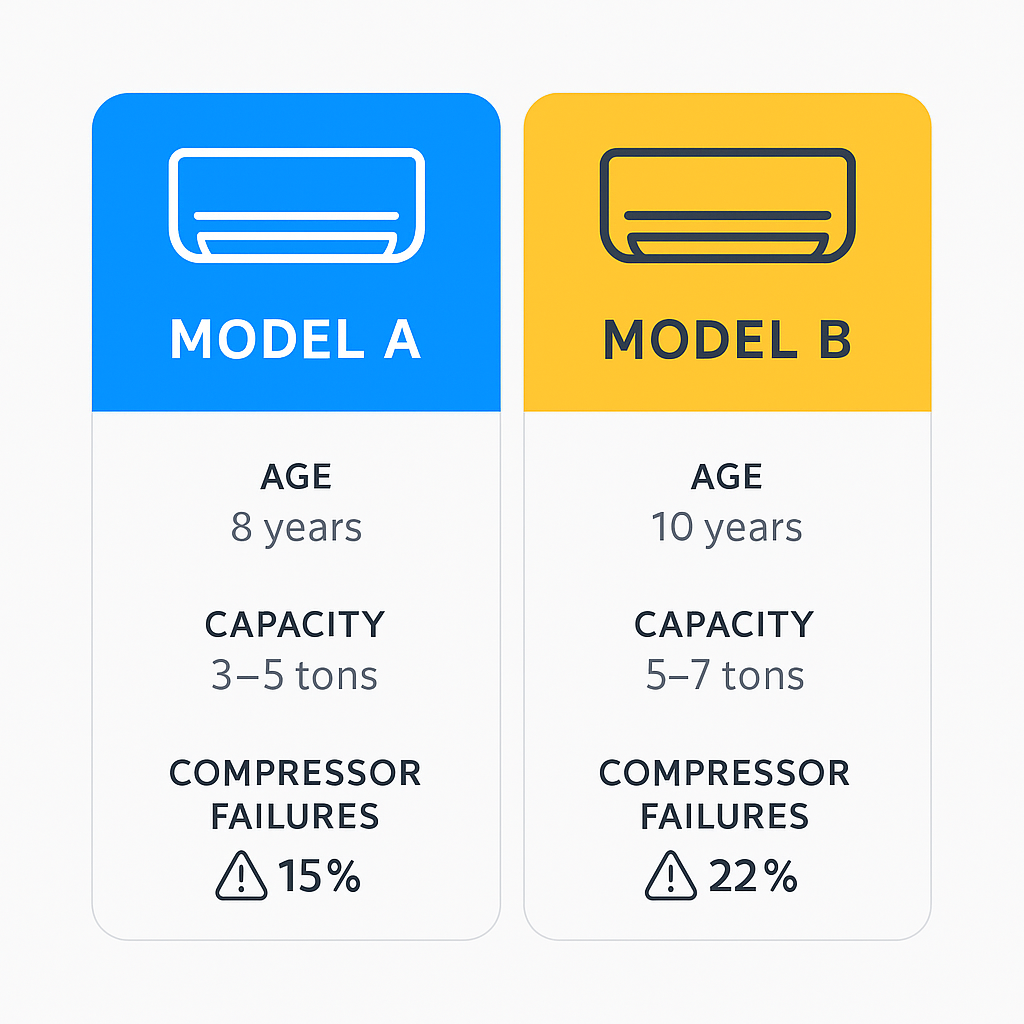

Side-by-side comparison of common compressor failure issues among popular air conditioning models used in Culver City.

Popular AC Models in Culver City

Culver City commercial sites most commonly install Goodman, Lennox, Trane, Carrier, and older Frigidaire units–each with market presence due to brand reputation and availability.

While modern models emphasize reliability, older versions–particularly those lacking enhanced safeguards or built-in diagnostics–are more susceptible to sudden compressor failure under heavy summer use.

Model-Specific Compressor Issues

Research and local repair trends reveal:

– Goodman and Frigidaire (older models) have exhibited higher compressor failure rates, particularly without regular service.

– Lennox and Trane units are generally robust but can still face compressor burnout due to electrical issues or age-related wear.

– Systems operating with rotary compressors can fail faster without adequate lubrication and airflow–a key issue in older retrofitted buildings.

Preventive Maintenance Recommendations

To minimize risk, professionals recommend:

– Scheduling semi-annual servicing with coil and filter cleaning

– Verifying proper refrigerant charge

– Monitoring and updating electrical components (such as surge protectors and relays)

– Promptly addressing unusual sounds or efficiency drops

Regular HVAC maintenance Culver City keeps AC units functioning optimally, prolonging equipment life and preserving warranty coverage.

Warranties and Guarantees for Emergency Repairs

Standard Warranty Coverage

Most Culver City providers stand behind their work with robust AC repair warranties Culver City, typically covering parts and labor for 90 days up to a full year, even for urgent or after-hours repairs. Compressor and major component replacements are usually prioritized in warranty protection.

Warranties include:

– Free or discounted re-service in the event of premature failure

– Clear terms, including coverage duration, conditions, and exclusions

– Peace of mind that high-value repairs are not a sunk cost if issues recur

Extended Guarantees and Service Plans

Some companies offer extended warranties or service plans for ongoing support. These plans may include:

– Coverage beyond standard terms (one to several years)

– Scheduled inspections and tune-ups

– Discounts on future emergency and commercial AC repair services

Investing in a service plan helps commercial clients avoid unplanned expenses and maintain consistent HVAC performance.

How to Verify Warranty Validity

Verifying your warranty is simple but critical:

– Keep repair receipts and warranty cards detailing work performed, dates, and part information

– Contact your provider (or manufacturer for OEM warranties) with equipment serial numbers to confirm terms

– Ask technicians to update system records after major repairs for digital or on-file warranty tracking

Understanding emergency AC repair warranties up front ensures you can act swiftly if issues re-emerge, avoiding confusion or unexpected costs.

Energy-Efficient AC Repair Solutions for Commercial Buildings

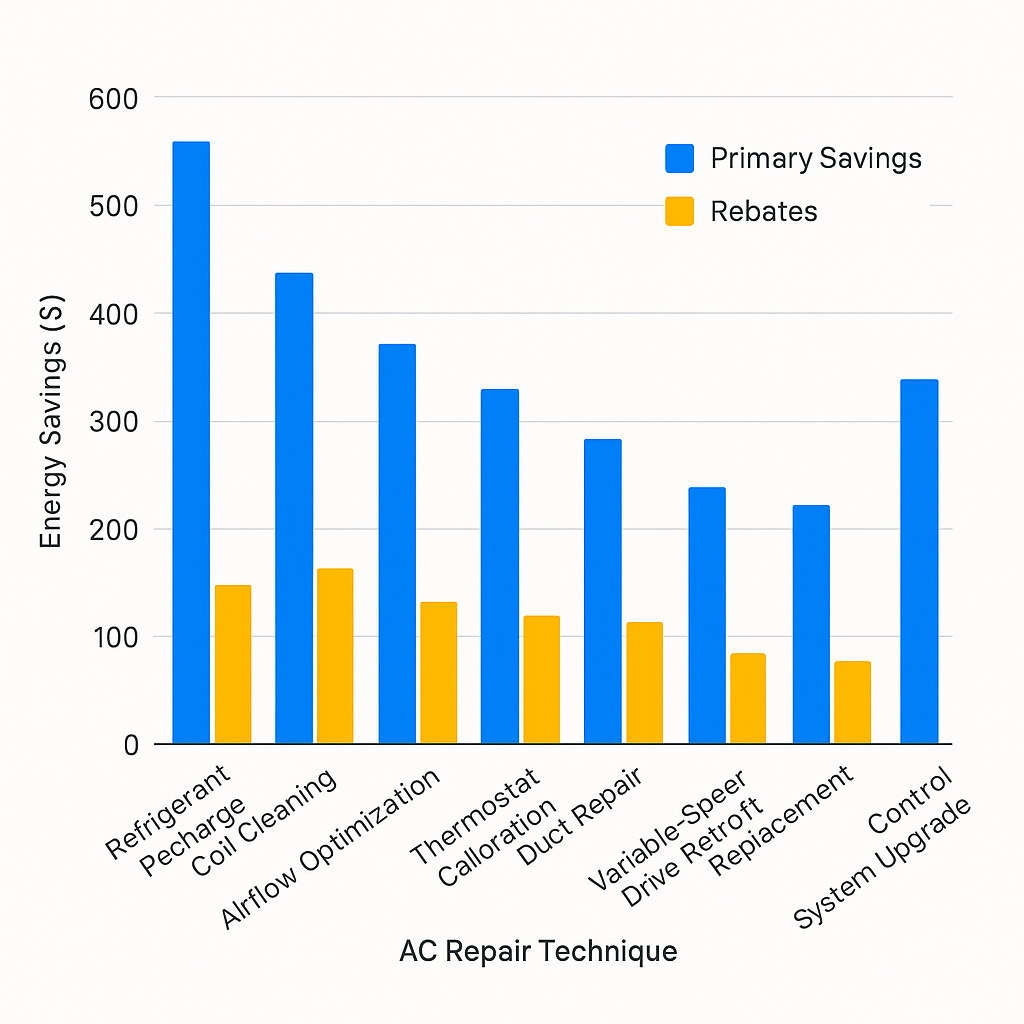

Data visualization showcasing energy savings and rebate opportunities from energy-efficient AC repair techniques in Culver City commercial buildings.

Benefits of Energy-Efficient Repairs

For Culver City’s commercial sector, energy-efficient AC repair delivers both immediate and long-term benefits, such as:

– Reduced energy consumption and operating costs

– Higher tenant satisfaction due to greater comfort and air quality

– Extended system lifespan and compliance with green building codes

Upgrades and repairs that focus on sustainability often yield significant returns on investment through lower utility bills and potential tax benefits.

Techniques to Enhance AC Efficiency

Modern repair and upgrade strategies include:

– Installing programmable thermostats and smart controls

– Adding variable frequency drives (VFDs) on compressors and fans

– Sealing ductwork to prevent leaks

– Using eco-friendly refrigerants approved under new standards

– Retrofitting for better airflow and heat exchange efficiency

These approaches form the backbone of energy-efficient AC repair solutions for commercial buildings Culver City, supporting both cost savings and environmental stewardship.

Rebates, Incentives, and Compliance

Culver City and California at large provide robust incentive programs for commercial energy upgrades:

– Utility rebates for installing ENERGY STAR-rated units and smart controls

– Tax credits for qualifying AC replacements and system improvements

– Compliance incentives for meeting or exceeding energy-efficient HVAC compliance requirements

Staying informed about rebates and incentives for AC repair and working with professional providers will maximize your financial returns and accelerate payback periods.

Maintenance Best Practices

To sustain energy savings:

– Adhere to a consistent commercial HVAC maintenance schedule

– Calibrate thermostats and monitor controls twice a year

– Replace filters and clean coils to optimize airflow

– Invest in recurring system diagnostics using building management tools

Implementing these best practices ensures maximum energy savings in HVAC repair over the lifespan of your AC investment.

Conclusion

Recap of Emergency Repair Essentials

Emergency compressor repairs are an unavoidable reality in commercial HVAC management. Understanding what constitutes an emergency, knowing the diagnostic and repair process, and being aware of the higher costs and warranty protections ensures you’re ready for sudden breakdowns. Swift action and proactive maintenance can substantially reduce the chances of recurring compressor issues.

Empowering Commercial Clients

By seeking professional AC repair Culver City and prioritizing qualified providers for HVAC repair near me Culver City, businesses safeguard their operations and investments. Embracing energy-efficient AC repair and compliance strategies delivers both cost savings and long-term resilience–ensuring year-round comfort for employees, customers, and visitors.

Contact a certified emergency AC compressor repair specialist in Culver City today to minimize downtime and ensure your commercial property stays comfortable and energy efficient.

Resources

Culver City Expert AC Repair | Service Genius

Culver City, CA | Lions Heating & Air Conditioning

Air Conditioner Repair Culver City CA | Belle Air Services

Comparing Rotary Air Conditioning Compressors (2025) | Rigid HVAC

UCLA – University of California, Los Angeles

Repair Air Conditioner Culver City – Crenshaw Heating and Air Conditioning

AC Repair Near Me Culver City – Crenshaw Heating and Air Conditioning

Furnace Repair Culver City – Crenshaw Heating and Air Conditioning

HVAC Cheviot Hills – Crenshaw Heating and Air Conditioning

Heating and Air Conditioning Contractors Near Me – Crenshaw Heating and Air Conditioning

AC Air Conditioner Repair Culver City CA HVAC Companies Culver City Heating And Cooling Contractors Culver City