Table of Contents

Introduction

In the fast-paced world of commercial kitchens, a sudden air conditioning failure can bring operations to a standstill. Proper temperature regulation is critical not only to maintain food safety and staff productivity, but also to satisfy health code compliance and guest expectations. Immediate, expert intervention is crucial–especially in high-heat kitchen environments where equipment and ambient temperatures already run dangerously hot. This is why choosing a partner specializing in emergency air conditioner repair for commercial kitchens can mean the difference between minimal downtime and catastrophic losses.

Why Rapid AC Repair Matters in Commercial Kitchens

A commercial kitchen without adequate cooling faces an exponential rise in risk: food spoilage, equipment malfunction, safety hazards, and potential revenue loss. Data shows that 65% of HVAC failures occur during peak hours, when restaurants and food service operations are busiest. Even a short delay in repairs can trigger a cascade effect–compromising health standards, driving away customers, and incurring fines for noncompliance. Immediate access to AC repair near me ensures your business can recover quickly, protecting both inventory and brand reputation.

Unique Challenges of Commercial Kitchen AC Systems

Commercial kitchen environments place extraordinary strain on air conditioning systems. High heat loads from cooking equipment, relentless humidity, and constant airflow filled with grease and particulates cause accelerated system wear. Grease buildup can clog coils and filters, while relentless cycling leads to premature compressor and thermostat failures. Only commercial kitchen HVAC repair by experienced pros addresses these unique technical challenges–ensuring targeted solutions that hold up in demanding conditions.

Energy Efficiency and Sustainability in Emergency Repairs

Today, commercial kitchen operators must balance the urgency of emergency service with a long-term focus on sustainability and cost control. Smart repairs now include energy-saving options–like smart thermostats and eco-friendly refrigerants–that can reduce costs well into the future. Integrating energy-efficient AC repair into your emergency protocol isn’t just environmentally responsible; it’s financially strategic, enabling you to achieve operational stability while supporting your green initiatives.

Common AC Issues in Commercial Kitchens

Commercial kitchens confront a unique set of HVAC challenges that demand vigilant monitoring and expert intervention. The relentless nature of these environments means AC systems are forced to perform under high stress, often leading to urgent issues.

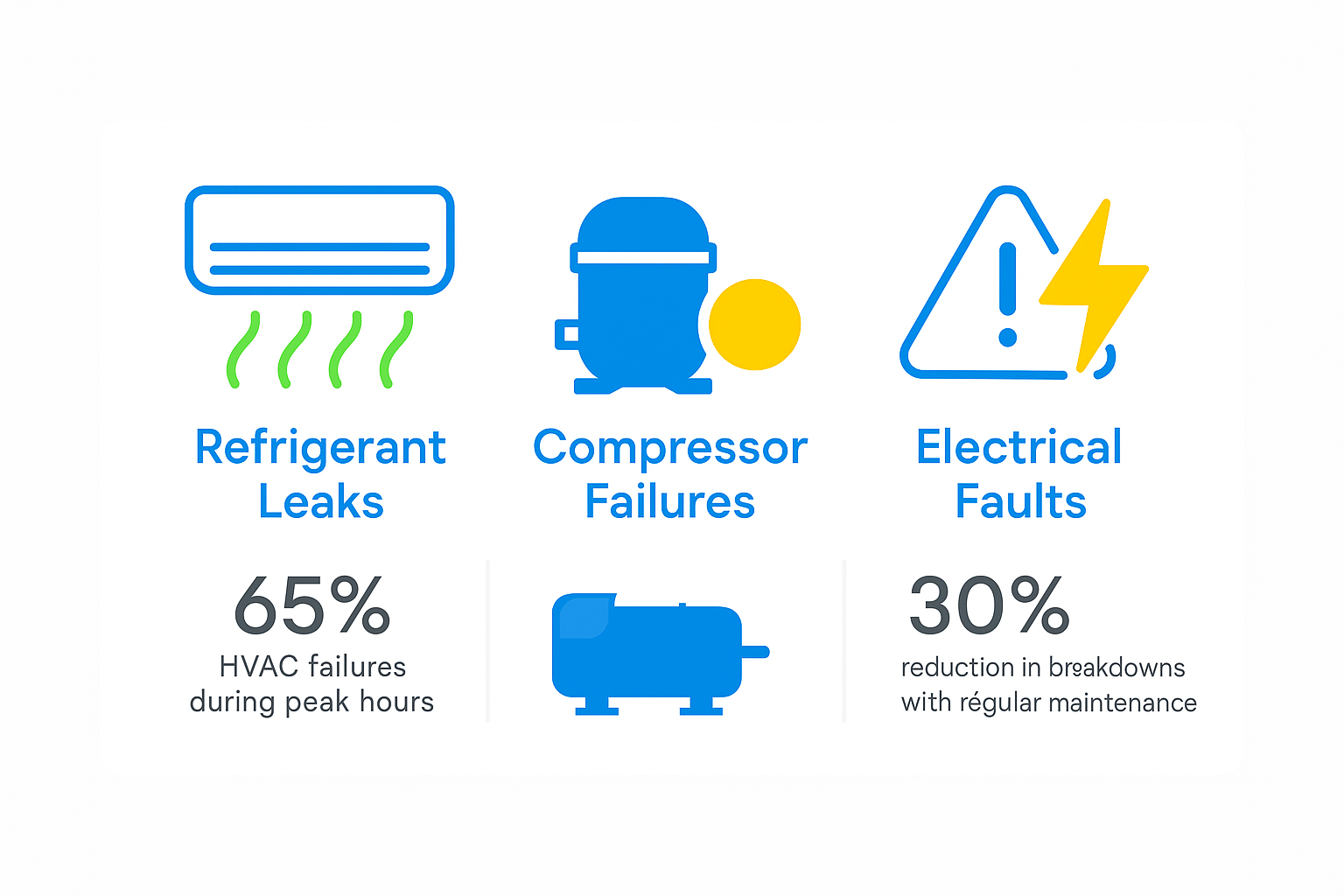

Infographic illustrating the most common issues faced by HVAC systems in commercial kitchen environments.

Refrigerant Leaks and Compressor Failures

One of the most pressing problems in commercial kitchen HVAC systems involves refrigerant leaks and compressor breakdowns. Leaks not only compromise cooling capacity but also create regulatory and environmental concerns due to strict rules on refrigerant handling. Compressor failures, meanwhile, represent a significant risk–these are the heart of the system and can halt cooling entirely. Technicians trained in commercial kitchen HVAC repair must act swiftly, as prolonged outages can lead to rapid food spoilage, excessive kitchen heat, and expensive system replacements if not remedied immediately.

Electrical and Thermostat Problems

The electrical demands in kitchens are exceptional, with heavy equipment running simultaneously. Faulty wiring, blown fuses, and overworked thermostats often precipitate breakdowns. Thermostat malfunctions result in inaccurate temperature control, which can endanger food safety and worker comfort. Addressing these requires prompt diagnostics and skilled repairs with a focus on AI diagnostics HVAC–increasingly used to quickly pinpoint faults and minimize downtime.

Impact of Grease and Heat on Components

Grease-laden air is a severe threat to AC longevity. Grease buildup coats evaporator and condenser coils, impeding heat conduction and raising system strain. Excessive kitchen heat further accelerates wear, particularly on insulation, valves, and electrical circuitry. Regular walk-in cooler maintenance and proactive system cleaning are critical for extending component life and avoiding costly emergencies.

Emergency AC Repair Process and Response Times

Getting a commercial kitchen back online quickly demands a precise, practiced response strategy. Today’s leading HVAC providers offer streamlined workflows and continuously trained technicians to ensure speed and quality.

Sequential process flow illustrating rapid diagnostics and typical emergency response times for AC repair.

Typical Emergency Response Times

Time is money in a bustling kitchen–and HVAC emergencies don’t wait for convenient hours. Industry leaders average 1-3 hour emergency response times, with some offering round-the-clock dispatch. Fast response is especially critical since 30% of breakdowns occur during weekends or holidays. Choosing a provider committed to emergency air conditioner repair for commercial kitchens is essential for uninterrupted service.

Rapid Diagnostic and Repair Techniques

Cutting-edge providers leverage AI-driven diagnostics and advanced tools to speed troubleshooting. Using AI diagnostics HVAC, technicians can identify sensor anomalies, detect leaks, and optimize repair paths before arriving on site, trimming expensive downtime. Field teams also come prepared with common replacement parts–compressors, fuses, thermostats–allowing for immediate repairs.

Specialist Technicians and Certifications

Only certified commercial kitchen HVAC specialists possess the unique knowledge and credentials necessary for safe, regulatory-compliant repairs. These technicians understand the nuances of high-heat environments, are versed in the latest safety codes, and can advise on system upgrades during emergencies. Relying on professionals that specialize in commercial kitchen HVAC repair or emergency HVAC repair services ensures repairs are performed safely and efficiently.

Preventing AC Breakdowns in Commercial Kitchens

Prevention is the linchpin of sustained success for any commercial kitchen. Instituting a robust maintenance protocol not only protects against emergencies but curbs energy use and extends system life.

Chronological timeline of maintenance and preparedness milestones to prevent AC failures.

Preventative Maintenance Strategies

Regular filter changes, coil cleaning, and scheduled inspections are essential. A well-crafted routine, such as those outlined in preventative maintenance for commercial kitchens, identifies minor issues before they become emergencies. Key steps include:

- Inspecting all electrical connections and controls

- Monitoring refrigerant levels and pressures

- Cleaning or replacing air filters and coils

- Verifying operation of thermostats and sensors

Proactive maintenance decreases unexpected breakdowns, with studies showing a 30% reduction in emergency repairs for kitchens on regular service schedules.

Energy-Efficient Upgrades and Repairs

Incorporating energy-saving parts for AC repair–like variable speed compressors and eco-friendly refrigerants–during repairs not only restores performance but delivers lasting savings. Investing in energy-efficient HVAC retrofit options pays off in reduced utility bills and may qualify your business for energy-efficient repair rebates.

Emergency Preparedness Planning

No kitchen can avoid every crisis, but robust planning–with clear protocols, backup cooling provisions, and staff training–enables fast recovery. Experts recommend building an HVAC emergency preparedness plan, mapping emergency contacts, and maintaining an inventory of critical spare parts. This approach ensures you’re always a step ahead, reducing the risk and impact of inevitable failures.

Cost Considerations for Emergency AC Repair

Budgeting for emergency AC repair requires transparency and data-backed insights into what drives costs and how to maximize value.

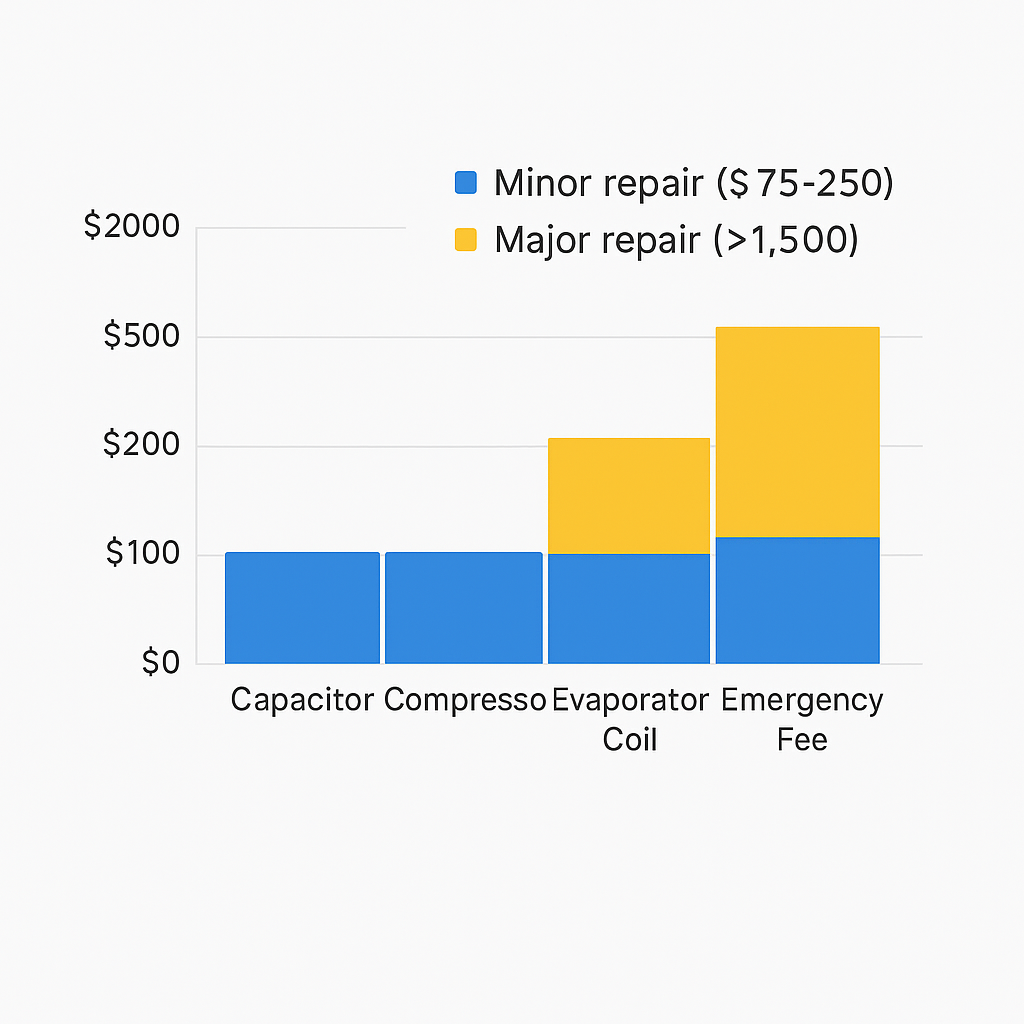

Chart detailing typical costs associated with emergency AC repairs for budgeting purposes.

Typical Repair Costs Breakdown

Costs range widely depending on the scope and urgency of the repair. Typical fees:

- Minor repairs (e.g., thermostats, filter changes): $75-$250

- Moderate repairs (e.g., leaks, capacitor replacements): $250-$750

- Major repairs (e.g., compressor/evaporator coil): $750-$1,500+

- After-hours or holiday emergency fees: usually an added 20-40%

Being proactive with AC repair cost research and regular service helps avoid premium rates for urgent cases.

Rebates and Incentives for Energy-Efficient Repairs

Many regions now offer energy-efficient repair rebates to help offset costs when installing eco-friendly HVAC components. State, utility, and even some equipment manufacturers provide financial incentives for upgrades that reduce energy consumption, making sustainability investments more accessible for businesses of all sizes.

Transparent Pricing and Service Contracts

The best providers offer upfront quotes and clear, written agreements, building trust and making budgeting easier. Comprehensive HVAC service contracts often bundle regular maintenance with emergency response, stabilizing expenses and delivering peace of mind.

Energy-Efficient AC Repair Options for Aging Units

Older AC units are especially vulnerable in the aggressive environment of a commercial kitchen. Upgrading with an eye for efficiency provides meaningful economic and environmental benefits.

Collection of icons illustrating energy-saving HVAC repair options for aging units.

Upgrading Components for Efficiency

Smart upgrades during repairs can yield substantial savings. Options include:

- Swapping out aging compressors for variable speed models

- Installing smart thermostats and controls for precise climate management

- Switching to eco-friendly refrigerants to reduce emissions and future-proof your system

These investments tie into energy-efficient AC repair, reducing both utility bills and maintenance requirements.

Assessing Repair vs. Replacement

Knowing when to repair or replace is crucial. As units age, repairs become less cost-effective, especially if major components like compressors or coils fail. Comprehensive assessment commercial refrigeration includes factoring in downtime risk, energy expenses, and eligibility for incentives. Consulting with trusted local technicians for AC repair near me ensures guidance specific to your kitchen’s needs and operating environment.

Available Rebates and Incentives

Explore every available incentive: many utilities offer substantial financial benefits for energy-efficient retrofits and new installations. These can dramatically offset upfront costs while also enhancing system reliability–just another reason to focus on energy-efficient HVAC retrofit strategies with your repair partner.

Conclusion

The realities of modern commercial kitchens demand more than basic repair–they require a rapid, expert, and sustainability-minded approach to HVAC emergencies. When every minute of downtime threatens not just revenue but food safety and team morale, only dedicated specialists offering emergency air conditioner repair for commercial kitchens can deliver continuous business performance. Prioritizing preventative maintenance and transparent pricing keeps budgets controlled and emergencies rare. By selecting certified professionals and embracing energy-efficient upgrades, your kitchen can run smoothly, safely, and with a reduced environmental impact.

Contact certified specialists today for fast, reliable, and energy-efficient emergency AC repair to keep your commercial kitchen running smoothly.

Resources

HVAC Emergency Preparedness for Businesses

The Ultimate Guide to AC Repair

How Much Does AC Repair Cost on Average?

Tips for Walk-In Box Cooler Maintenance

Market Trends and Innovation in HVAC Industry

Smart Technology in Urban Infrastructure and HVAC

AI and Machine Learning in HVAC Optimization

Marketing Strategies and Brand Images

Emergency HVAC Repairs

Air Conditioning Services

AC Repair Near Me in CA

AC Repair & Replacement Cost in California

Air Conditioner Repair Near Me Furnace Repair Near Me CA AC Repair Near Me